Light Rotating X-ray Targets

Light Rotating X-ray Targets

ACERDE offers graphite or carbon-carbon composite targets coated by CVD with a Tungsten-Rhenium layer. The use of a lightweight target enables increased rotation speed, decreasing the bulk track temperature. Low mass targets could also permit off-axis rotation for greater X-ray generation efficiency.

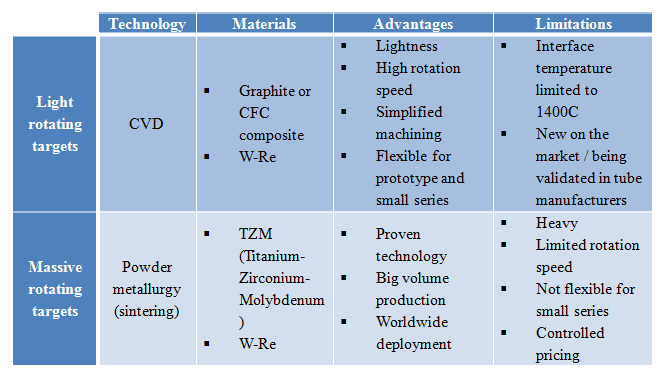

Below, a comparative table between ACERDE light rotating targets vs. typical massive rotating targets currently on the market.

Light Rotating Target Manufacturing Process

Light rotating targets are made from a graphite or carbon-carbon composite substrate coated with a Tungsten-Rhenium layer. The manufacturing process is as follows:

Dimensional control and cleaning steps are carried out between some of these steps.

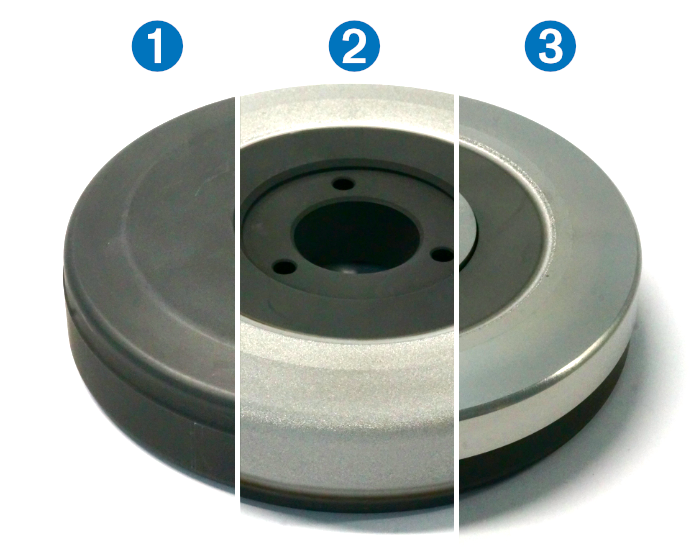

The scheme below shows an anode at different stages of the process:

1. Bare graphite or composite substrate (before deposition);

2. Substrate coated with a Tungsten-Rhenium layer, as-deposited;

3. Substrate coated with a Tungsten-Rhenium layer after grinding.