Reclaim of Used Targets

Most modern high power x-ray targets are heavy assemblies manufactured via powder techniques.

Most modern high power x-ray targets are heavy assemblies manufactured via powder techniques.

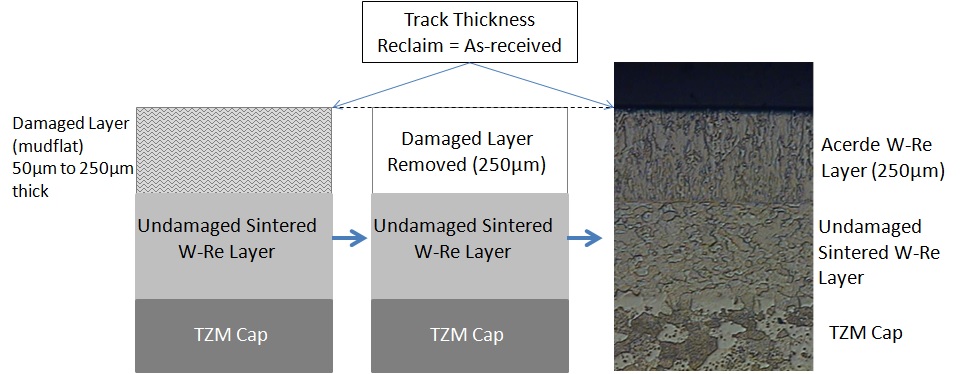

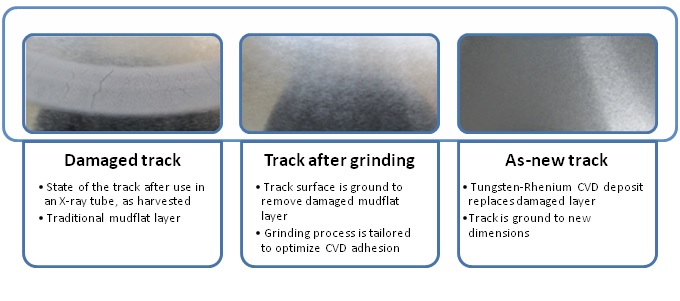

During use, only a thin layer of the tungsten surface is altered. Acerde utilizes its proprietary CVD process to replace this layer and give the targets multiple lives.

The reclaim process entails:

- Focal track machining, to remove mudflat layer;

- CVD deposition of a 100%-dense Tungsten-Rhenium layer

- Final grinding to target specification.

The diagram below shows the state of the track between the different steps.

The CVD-deposited material thickness is equivalent to the thickness removed by grinding to ensure the target dimensions remain in specification.